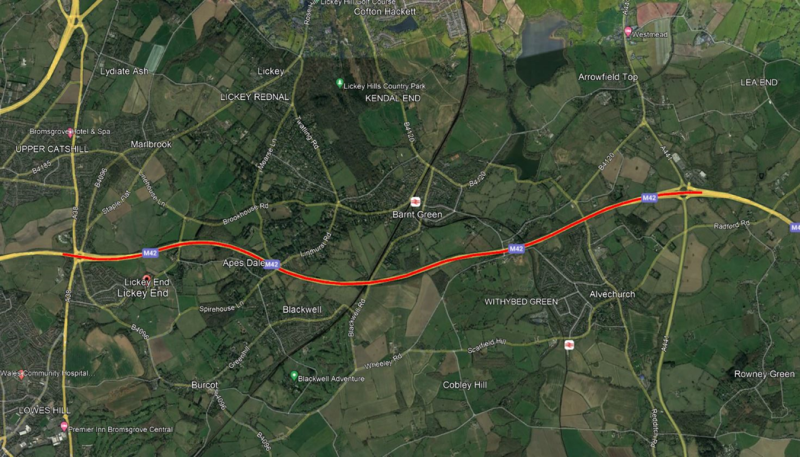

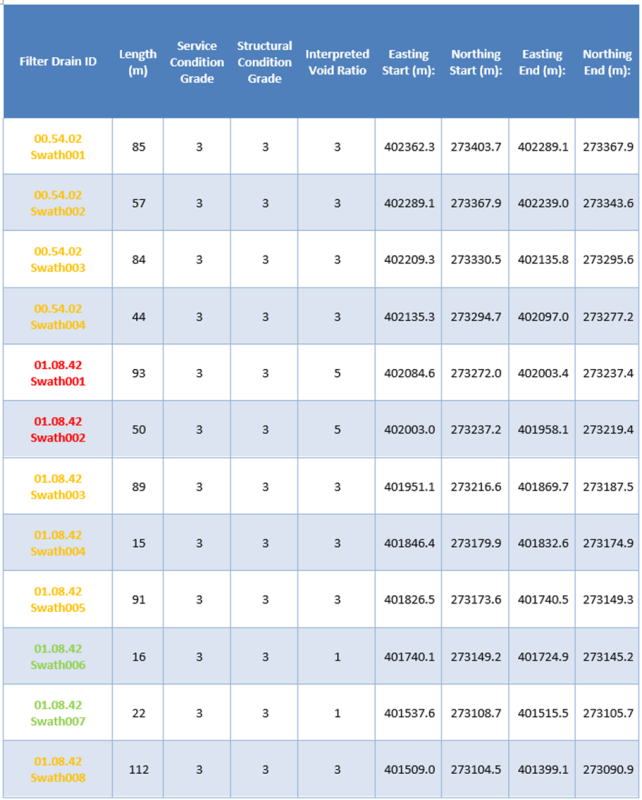

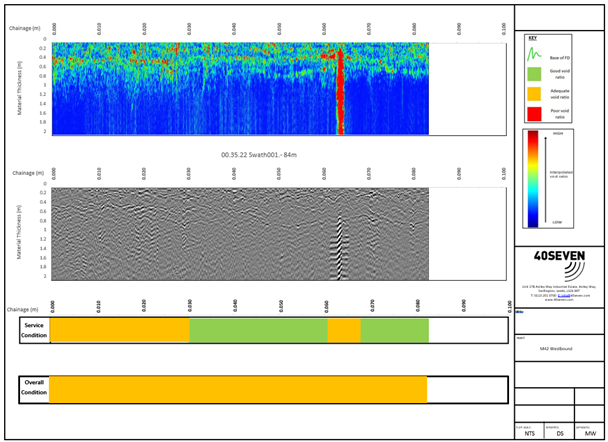

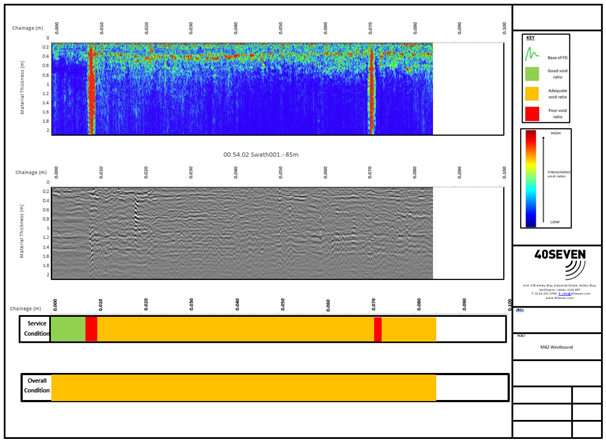

We were tasked by our client to determine the condition of the filter drains between Junction 1 and Junction 2 of the M42. A distance of 6725m was covered by a total of 54 swaths on the West and East bound verges.

Filter drains are gravel filled trenches that collect and transport water as well as treating pollution. A trench is filled with free draining gravel, together with a perforated pipe in the bottom to collect the water. Over time their ability to remove water from the pavement surface and surrounding area degrades as result of sediment build up within the media. Floating water brings further blocking agents that fill the existing voids within the media. Those blocking agents can be small size particles, such as sand and grit.

The objective of the survey therefore was to measure the extent and severity of the clogging within the filter media in accordance with the UK Highways Agency’s Design Manual for Roads and Bridges CS551: Section 5.